What use-cases are possible, what use-cases have been developed so far?

omlox is based on an open member community. One of its working groups is developing use cases, how the world's first open locating standard can be used. The variety of use-cases where omlox can provide value is almost endless and more than 140 use cases have been identified so far, as location-data is an important element in today’s hypermobile world.

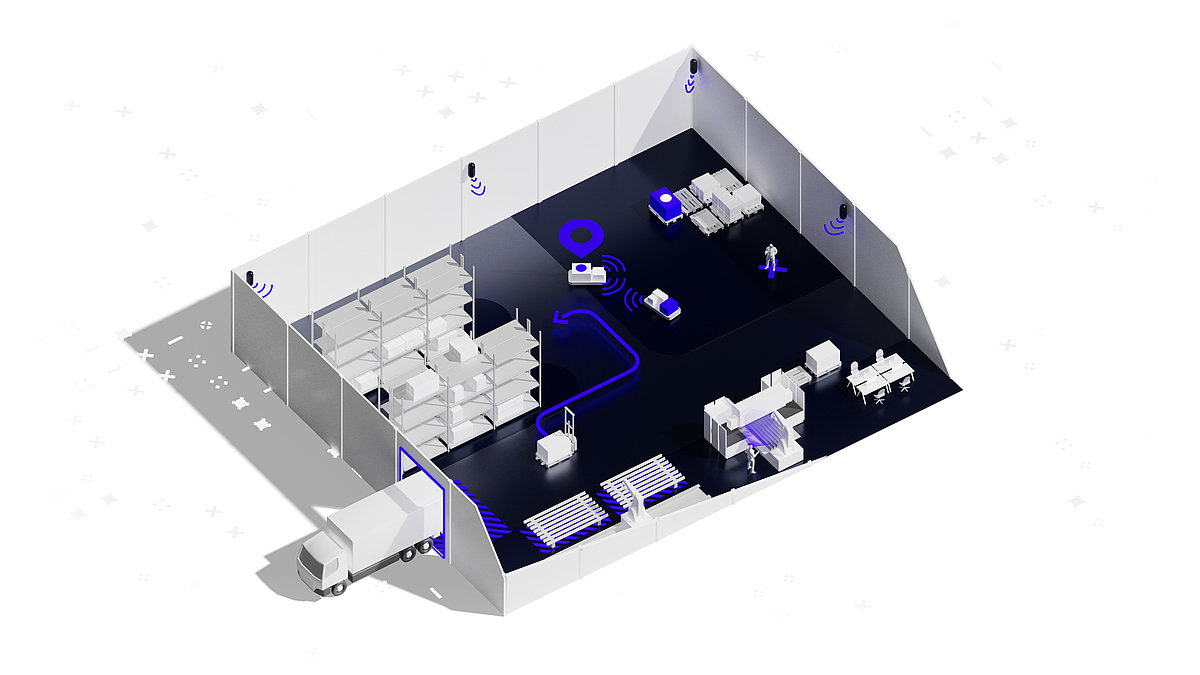

Track and Trace Applications

Those applications locate all sorts of assets in various environments, from shopfloor, warehouse to yards or even in-between different sites. The type of assets is very manifold, from products, to tools, humans or means of transportation like AGVs, forklifts, trucks, or ships. Main benefits for those “Track and Trace” applications are reduced manual search, a more efficient asset usage, an up-to-date inventory, and less CAPEX.

Location-based Automation

When things change their location, this is often also an indication of a certain step in a large process-chain, e.g., a product is been built in a step-based manner at different production station in a plant. Having access to location-data and been able to use geo-fencing and proximity events, can facilitate a location-based automation, for example by presenting the relevant information to a worker at a given station or by automatically generating shipment list, based on the goods on a truck.

Operation and Maintenance

Maintaining and operating mobile assets can be a challenging task, especially when they are used in dynamic indoor environments or when compliance rules need to be applied. Having the flexibility of omlox to locate mobile assets precise via UWB or any other locating technology and using the some locating technology to give maintenance staff an orientation in unknown locations, can streamline the complete process. This especially true when applying modern user-interface technologies like AR, where workers can navigate and find things hands free.

Automized, optimized and sustainable Material flow

In today’s production and intralogistics more and more autonomous robots are being deployed – stationary and mobile ones. It becomes a challenge to orchestrate the movements of all the mobile elements in a streamlined and safe manner. Omlox enables a holistic overview of the position and movements of all things in those environments and allows for an optimized material flow, beyond considering only one means of transportation or on asset type. In addition, this allows also to optimize the material flow considering energy consumption and carbon-footprint.